Dimensional Calibration Lab

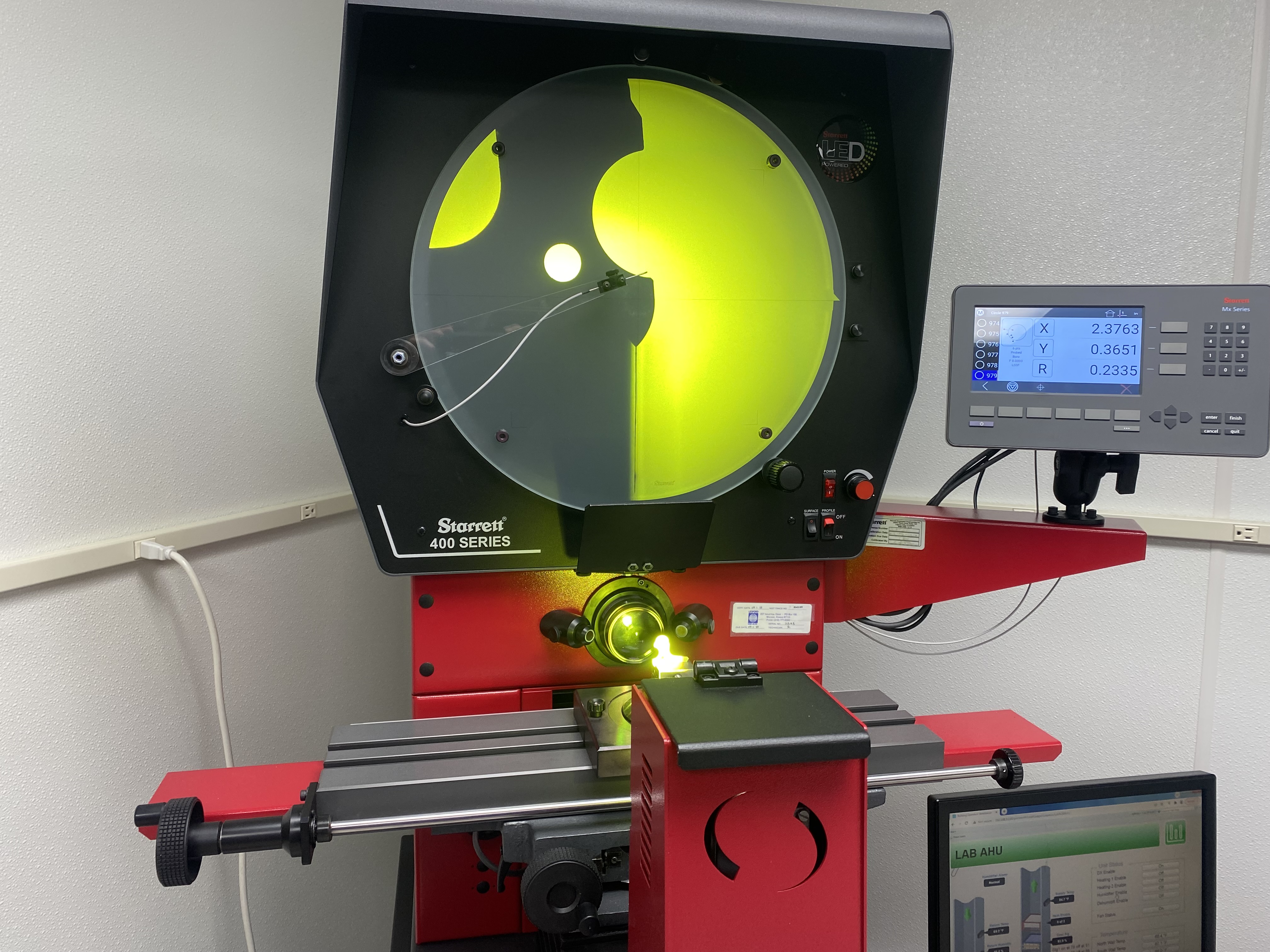

Ledford Gage Lab, Inc. exceptional facility was designed with dimensional calibration in mind. Opened in 1998, the laboratory has double wall construction with a four inch air envelope allowing optimum environmental control. Temperature and humidity are controlled by a CSI computer system which samples every thirty seconds and adjusts every three minutes as needed. A 25 inch slab floor, R-60 insulation and a .0101 micron filter system ensure the conditions necessary for measurements in the millionths.

“Simple Acceptance as defined by ILAC G8 is used when a statement of conformity (pass/fail) is given. When a 4 to 1 TUR is not obtainable both parties agree to a shared risk of false pass/fail of the raw data. In this case no statement of pass/fail can be given, the raw data is the customer’s sole responsibility to determine if the results meet their specific needs.”

- Expedite (1-Day 50% Added)

- Expedite (2-Day 35% Added)

- Expedite (3-Day 25% Added)

- Minimum Charge - Lab Orders $26.75

Angle Gage Blocks

Gage Blocks - Steel to 4"

Gage Blocks - 5 to 20" minimum 20.00 + .50 per inch

Gage Blocks Carbide to 4"

Accessory Set

Accessory

Gage Blocks - Ceramic to 4"

Gage Blocks - Grade 1

Gage Blocks - Ceramic Grade 1

Length Standards to 6"

Length Standards 7 - 30" (per inch)

Length Standards 31 - 54" (per inch)

Length Standards 55 - 120" (per inch)

Micrometer Master (per Reading)

Caliper Master (per Reading)

Depth Micrometer Master (per Reading)

Standard Reference Bar to 12"

Standard Reference Bar 13 - 19"

Standard Reference Bar 20 - 25"

Standard Reference Bar 26 - 37"

Optical Flats 0 - 4"

Precision Balls

Gear Wires (2 pc set)

Thread Wires (3 pc set)

Caliper to 6"

Caliper 7 - 12"

Caliper 13 - 24"

Caliper 25 - 36"

Caliper 37 - 48"

Caliper 49 - 60"

Caliper 61 - 72"

Caliper 73 - 120"

Bore Gage - Dial

Dial Indicator to 1"

Dial Indicator to 2"

Dial Indicator to 3"

Dial Indicator to 4"

Dial Indicator to 5"

Dial Indicator to 6"

Dial Mikrokator

Intrimic

Micrometer - Depth to 4"

Micrometer - Depth to 6"

Micrometer - Depth to 9"

Micrometer - Depth to 12"

Chamfer Gage

Micrometer - Inside to 6"

Micrometer - Inside to 12"

Micrometer - Inside to 24"

Micrometer - Inside to 36"

Micrometer - Inside to 48"

Micrometer - Inside to 60"

Micrometer - Inside to 72"

Micrometer - Inside to 84"

Micrometer - Inside to 96"

Micrometer - Inside to 120"

Adjustable Micrometer 0 - 4"

Adjustable Micrometer 7 - 12"

Adjustable Micrometer 13 - 24"

Adjustable Micrometer 25 - 30"

Adjustable Micrometer 31 - 40"

Adjustable Micrometer 41 - 60"

Micrometer - Outside 0 - 6"

Micrometer - Outside 7 - 12"

Micrometer - Outside 13 -24"

Micrometer - Outside 25 - 36"

Protractor - Digital

Protractor - Mechanical

Radius Gages (per leaf) w/o Readings

Radius Gages (per leaf) w/ Readings

Screw Pitch Gage (per leaf)

Employee Tool Box

Coordinate Measuring Machine 30"

Coordinate Measuring Machine 36"

Coordinate Measuring Machine 48"

Coordinate Measuring Machine 60"

Coordinate Measuring Machine 72"

Coordinate Measuring Machine 96"

Coordinate Measuring Machine 108"

Coordinate Measuring Machine 120"

Universal Length Measuring Machine

Electronic Amplifier

Height Gage - Digital to 12"

Height Gage - Digital to 18"

Height Gage - Digital to 24"

Height Gage - Digital to 36"

Height Gage - Digital to 48"

Height Gage - Digital to 60"

Height Gage - Vernier to 18"

Height Gage - Vernier to 24"

Height Gage - Vernier to 48"

Height Gage - Vernier to 72"

Height Master (per Step)

Riser Block

Optical Comparator to 15"

Optical Comparator to 36"

Hardness Tester - Brinell

Hardness Tester - Rockwell

Hardness Tester Combination

Hardness Test Blocks

Durometer

Supermic to 5"

Supermic 6 - 10"

Supermic 11 - 24"

Surface Plate - Minimum Charge

Surface Plate - per Square Foot

Surface Finish Machine

Surface Finish Standard

1-2-3 Block

Angle Plate to 8"

Angle Plate 9 - 12"

Angle Plate 13 - 18"

Cylindrical Square

Level - Machine

Level - Master

Level - Electronic

Parallel to 12"

Parallel 13 - 24"

Parallel 25 - 48"

Parallel 49 - 60"

Parallel 61 - 120"

Sine Bar to 12"

Sine Bar 13 - 20"

Sine Plate - Compound

Square to 12"

Square 13 - 24"

Straight Edge to 24"

Straight Edge 25 - 60"

Straight Edge 61 - 120"

V-Block

Acme Thread Ring 0 - 2"

Acme Thread Ring 2 - 4"

Acme Thread Ring 4 - 6"

BSPT/BSP Thread Ring 0 - 2"

BSPT/BSP Thread Ring 2 - 4"

BSPT/BSP Thread Ring 4 - 6"

Buttress Thread Ring 0 - 2"

Buttress Thread Ring 2 - 4"

Buttress Thread Ring 4 - 6"

Cylindrical (Plain) Ring Gage .040 - 2.000"

Cylindrical (Plain) Ring Gage 2.001 - 5.500"

Cylindrical (Plain) Ring Gage 5.501 - 11.000"

Cylindrical (Plain) Ring Gage - Above 11.000"

Spline Ring Gage

Thread Ring Gage 0 - 1"

Thread Ring Gage 1 - 2"

Thread Ring Gage 2 - 4"

Thread Ring Gage 4 - 6"

For Non-Standard Pitch Diameter Add

Thread Ring Gage Above 6"

Thread Snap Gage 0 - 2"

Thread Snap Gage 2 - 6"

Thread Snap Gage - Non-Standard

NPSM Thread Ring 0 - 2"

NPSM Thread Ring 2 - 4"

NPSM Thread Ring 4 - 6"

NPT - NPTF - ANPT Thread Ring 0 - 2"

NPT - NPTF - ANPT Thread Ring 2 - 6"

NPT - NPTF - ANPT 6-Step Ring 0 - 2"

NPT - NPTF - ANPT 6-Step Ring 2 - 6"

Metric Thread Ring 1 - 25 mm

Metric Thread Ring 25 - 51mm

Metric Thread Ring 51 - 102mm

Metric Thread Ring 102 - 152mm

Luer Taper Rings

Taper Rings

Air Probes - All

Acme Thread Plug 0 - 2" (per End)

Acme Thread Plug 2 - 4" (per End)

Acme Thread Plug 4 - 6" (per End)

BSPT/BSPP Thread Plug 0 - 2" (per End)

BSPT/BSPP Thread Plug 2 - 6" (per End)

Buttress Thread Plug 0 - 2" (per End)

Buttress Thread Plug 2 - 4" (per End)

Buttress Thread Plug 4 - 6" (per End)

Buttress Set Plug 0 - 4" (per End)

Buttress Set Plug 4 - 12" (per End)

For Non-Standard Pitch Diameter Add

Pin Gages (Class ZZ)

Plain Plug Gages 0 - 2" (per End)

Plain Plug Gages 2 - 6" (per End)

Plain Plug Gages 6 - 12" (per End)

Spline Plug Gage (per End)

Thread Plug 0 - 1" (per End)

Thread Plug 1 - 2" (per End)

Thread Plug 2 - 3" (per End)

Thread Plug 3 - 4" (per End)

Thread Plug 4 - 6" (per End)

Thread Plug 6 - 12" (per End)

Thread Set Plug 0 - 4" (per End)

Thread Set Plug 4 - 12" (per End)

NPSM Thread Plug 0 - 2" (per End)

NPSM Thread Plug 2 - 4" (per End)

NPSM Thread Plug 4 - 6" (per End)

NPT - NPTF - ANPT Plug 0 - 2" (per End)

NPT - NPTF - ANPT Plug 2 - 6" (per End)

NPT - NPTF - ANPT 6-Step Plug 0 - 2" (per End)

NPT - NPTF - ANPT 6-Step Plug 2 - 6" (per End)

Metric Thread Plug 0 - 25mm (per End)

Metric Thread Plug 25 - 51mm (per End)

Metric Thread Plug 51 - 102mm (per End)

Metric Thread Plug 102 - 152mm (per End)

Metric Set Plug 0 - 102mm (per End)

Metric Set Plug 102 - 305mm (per End)

Luer Taper Plugs

Taper Plugs

Cable Tensiometer w/Card

Cable Tensiometer - New Card

Force Gage to 250 lbs

Force Gage above 250 lbs

Gram Gage

Torque Wrench to 250 ft/lbs

Torque Wrench Above 250 ft/lbs

Torque Watch

Torque Tester

Torque Transducer

Weights - Avdp Class 6 & F

Weights - Gram Class 3 thru F

Crimping Tool

Film Thickness Gage

Digital Film Thickness

Feeler Gage (per Blade)

Readings for Rule 6 - 72" (per Reading) Add

Rule 6 - 36" w/o Readings

Rule 37 - 72" w/o Readings

Tape Measure to 25 ft

Tape Measure to 50 ft

Tape Measure to 100 ft

Machine Inspection - Laser (per Hour)

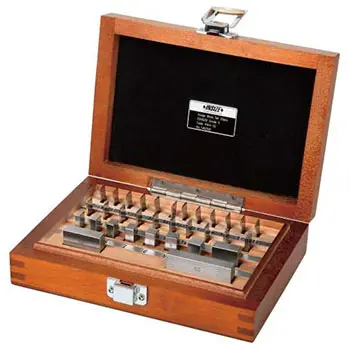

Metric Gage Block Sets from Ledford Gage

Engineered with utmost precision, our gage block sets are indispensable instruments for industries requiring exact measurements and calibration.

Crafted from top-grade materials like steel, carbide, or ceramics, our gauge blocks exhibit exceptional accuracy and durability. Each block undergoes rigorous calibration processes to ensure adherence to stringent standards, guaranteeing reliable performance in various applications.

Our metric gauge block sets feature a comprehensive range of sizes, meticulously marked with metric units such as millimeters or micrometers. Whether it's calibrating instruments, setting up machinery, or conducting precise measurements, Ledford Gage metric gauge block sets provide the precision and reliability you need.

Trust Ledford Gage for your metrology needs, and experience the difference precision makes in your operations.

Dimensional Air Gauges from Ledford Gage

Dimensional air gauges are advanced measurement tools utilized for accurately determining dimensional attributes like diameter, thickness, concentricity, and roundness of parts. Unlike traditional mechanical gauges, they operate through a non-contact method employing compressed air. These gauges incorporate components such as sensing elements, air supplies, and control units, with the sensing element often featuring nozzles or jets emitting controlled streams of air onto the part's surface. By measuring variations in airflow or back pressure resulting from the interaction with the part's surface, dimensional characteristics are determined swiftly and precisely. This non-contact approach offers notable advantages, including the ability to measure delicate or complex parts without causing damage, making them highly suitable for industries like automotive manufacturing, aerospace, and medical device production where precise measurements are paramount. With their capability to provide fast and accurate measurements, particularly for intricate geometries or challenging-to-reach features, dimensional air gauges are indispensable tools for maintaining quality standards and optimizing manufacturing processes across a range of industries.